|

We have spent the last couple of weeks, turning the coffee on the drying trays, and checking it daily. When fully dried, the parchment beans have their own distinct odour: rather like fresh hardwood sawdust, with a hint of vanilla, and almonds. When fully dried, the bean will have a water content of between 9 and 12.5%: of course there are modern test meters to check it, or just use the old method, the "bite" test: if you can bite into the bean, it is not fully dried!! BUT: bite gently!! a fully dried bean is quite capable of cracking a tooth!! As the beans dry out, they shrink inside the outer "husk", and are called "parchment beans", as that is the colour of them, the outer husk is very "crisp", and hard; but being very thin, it is brittle, and easily crushed between the fingers, to reveal the "green bean" inside. Although "green" is hardly appropriate: best I can describe the colour, it is a "slate grey", with a hint of blue/green: the lower quality beans are of a paler colour, less blue, and a greater green component in the colour, the worst of the beans appearing almost white.

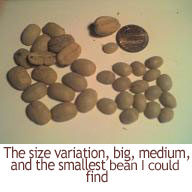

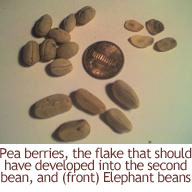

Amongst the parchment beans, there will be a few "black" beans: these are the unripe beans that were picked, the skins too tough for the pulper to break, and they end up totally dry, in the outer skin, and are almost black. When the beans are fully dried, they are put in semi air-porous sacks, and stored in a "cool, dry place", for at least 6 weeks, to "rest": the parchment husk, protects the bean inside, from any damp, mould, etc. We like to stir the beans up, every week, to ensure that they get air contact, as evenly as possible, throughout the whole sack. Great care must be taken to ensure that nothing with a "strong smell" gets near the resting beans, as they will take up the smell (hydrocarbons, and household cleaners, are the worst!). For longer term storage, the bags are checked every week, with the "nose", and the slightest smell of damp, or mould; and the beans are put out in the sun for a couple of days, to keep them fully dry. Parchment beans. The bean is usually smaller, and egg shaped, without the flat side, around 5% of beans are pea berries. Elephant beans: where 3 beans develop in the pod, possibly 1 in 250 cherries; they each have 2 flat sides, and are usually longer and thinner than normal beans. By the time the first batches of parchment beans are ready to finish, we are into the late spring, the dry season, more sun, less rain and damp; the beans are put out in the sun for a couple of days, to ensure they are fully dried out (whilst resting, they can absorb some water from the air) and get the parchment husks really warm and "crisp". Then into the "huller", to remove the parchment husks: the machine is similar to a hand operated meat mincer, the parchment beans go into a chute on the top, and as the handle is cranked (by hand) a big screw forces them through the barrel of the machine, crushing them, cracking, and separating the outer husk. The mixture of beans and trash, comes out at the bottom of the machine, less than about 5% of the beans pass through the machine, unhulled.

And what a bargain the huller turned out to be! We bought a real old one, so worn out that it did not work at all; cost us less than US$10: I made a couple of new bearings for it (out of old tin cans, heavy grease, and some acetate sheeting) and it now works perfectly!! Before we got the machine, the beans were hulled by being beaten with a large stick (think of Hercules, and his big wooden club!) inside a sack, which had the adverse effect of squashing, and damaging some of the beans, as well as being very slow, and really hard work!! It can also be done in a large pestle and mortar, but it is very difficult to get it just right: breaking up the parchment, without damaging too many of the beans. Next job is to separate the beans from the trash: (winnowing) in the old days, it would be done by tossing the mixture, on a tray, and allowing the wind to blow away the trash: we now use a large office type, fan: pouring the mixture slowly through the air stream, the beans fall straight down, and the trash gets blown away: to get them fully separated, we have to repeat the process a couple of times: and "Voila", a tray of fresh, green beans!! The electric fan (which never actually touches the coffee) is our only "modern/power" operated, input to the processing: both the pulper, and the huller, whilst being "machines", are hand operated, and are direct substitutes for what used to be done by hand, they do nothing "non-traditional" to the coffee, and merely speed up the processing, without any other "effects" on the coffee. The pulper, certainly, improves the coffee, as it allows us to pulp the coffee, in quantity, very much more quickly, than by hand. To pulp the coffee, by hand; requires that each beans is squeezed between the fingers, in a bowl of water, until the beans "pop" out of the cherry: VERY hard, and painful, on the fingers!! as well as being very slow. We are now ready for the next part of the process: test again (meter or bite test) to check on water content: and either a day or so, in the sun, or straight to the last few steps in the processing. Green beans, even fully dried, are susceptible to all sorts of contaminations, and unless kept in very carefully controlled conditions, will soon "spoil": to minimise any spoilage, we roast all our beans as soon as possible, after hulling, sorting and grading, them. We use a sieve to sort the green beans, separating out the larger beans from the smaller ones. The top quality beans are sorted out at 17 or 18 (coffee bean size is measured in 64ths of an inch) which very closely matches the hole size of 1/4 inch wire square mesh, which is what we use. A lot of the trash beans, the remaining bits of the parchment, and most of the pea beans, sieve out, along with the smaller beans. We take out the pea beans, and treat them separately (many people believe they make the best coffee, and will pay a lot more money for them: to my palate, no difference is detectable). We keep the undersized beans, and use them for "emergency" purposes: they make excellent coffee, but slightly lacking in the fullness of flavour, of the best, larger, beans.

Some of the beans are still (wholly or partially) covered in a "silver skin", the remnants of the membrane surrounding them, in the pod. Commercial processors use a machine to rub this skin off, by friction: but there is a problem, the friction produces heat, and the beans must not be allowed to reach a temperature of 120F, or the flavour of the coffee is "impaired"! Most of this silver skin, is rubbed off by the huller, the rest by hand, during grading, but the remnants cause no problems, oxidising during the roasting process, and the "flakes" are very easily removed with a simple sieve. Then on to the grading: a most tedious and boring, operation; bordering on "mind numbing" in its tediousness! Each and every individual bean, is checked by hand, any that are damaged, discoloured, or show any sign of insect damage; are rejected, as are any undersized beans that escaped the sorting. The pea beans are also separated out, and kept apart from the rest of them.

Grading: every bean, individually, by hand!! A few beans escape the hulling process, and still have the parchment skin attached: these are sorted out, and put back through the huller. After the initial grading, we double check for any undersized beans, with a more precise, sorting screen, made from a plastic tray, with precisely sized holes drilled in it. The trash beans, and any bits of parchment, are added to the compost heap, the smaller beans, and those with minor damage, we store for our "emergency" use; and I reserve the pea beans, for a special friend. 16 plus: screen grade beans, account for around 75% of the green beans, the pea berries, another 5%: undersized, and beans with only very minor faults (our emergency supply: commercially, this would have to be roasted and ground, before being sold into the local market) another 15 to 20%. The trash (for the compost heap) varies from as little as 2%: up to 10%, in the early picking. The very top grades of commercial, coffee are graded 3 times: passing through the hands (and under the eyes) of 3 different people, before a final check by the "boss", OK's the batch. Up here, I grade them once, then Chris does a double check, and I go through them again, before we roast them. Unfortunately, my camera does not have a lens with a focus capability, to take decent pictures of the reject beans, (as you may have noticed in some of the earlier, pictures) so I will try and describe them:- "Black" beans: shrivelled up, and black in colour; usually the beans destroyed by the coffee borer beetle. Colour variations, variations away from the "slate grey" colour, pale, greener, or totally, pale and "off-colour". "Mouldy" beans: some of them are really beautiful!! covered in small spots of all sorts of different colours. Physically damaged beans, the inevitable few that get "squashed" during processing: and those with minor insect damage, often only visible as a small, black patch, at one end. Any bean with an imperfection, visible to the naked eye, is rejected; a few escape the grading, but not many, and the defects in the bean are very minor, and do not affect the flavour of the brew. The local coffee board has precise specifications for the quality of the sorting and grading: with a 4% allowance (the machine tolerances) for the smaller beans that just pass through the sorting process; and a 3% allowance for other defects, most of which are so small, and minor, the graders just cannot see them, and the defects are only visible when each individual bean is hand checked, under magnification (which is exactly what the coffee board does, with a random sample, from every batch of coffee, before allowing it to be exported). The last process is the "density separation", because the beans vary in density, if all roasted together, they will not roast, evenly, the simplest method we have found, is to use the office fan, and pour the beans in front if it, the heavier ones separating from the lighter ones, just needs careful positioning of the collecting trays. I have yet to find anyone who claims to be able to detect the slightest flavour difference, between the beans that come out of the "density separation". It is my preference (or will be, when we start getting coffee, in "saleable" quantities, a few years yet!) to supply customers with Green Beans, most real coffee lovers, these days, have either their own roaster, or a "friend" with one; and can roast the beans exactly to their own preference. My choice is for a border-line, full dark roast, just short of any bitterness developing in the brew: the point just before the "roasting" flavour, overpowers the flavour of the coffee. I only hull, sort and grade the coffee, in sufficient quantities, for immediate use: and keep all longer stored beans, as parchments: occasionally this "back-fires" and we don't get sufficient sun, to dry off the parchments: so it is time to roast a batch of the "reject" beans (kept in tightly sealed plastic bags, somewhere cool, and dark) or in extreme cases, we are reduced to "super-market" coffee! Roasting (or parching, in the local "speek") Our "own drinking" coffee, is roasted in a large, thick, "Dutch Pot", over an open wood fire (just the way it has been done for a thousand years) whilst it leads to a bit of an "uneven" roast, it does give the brew a slight, and very pleasant, smoky tang, from the "fragrant woods" (Cedar, Mahoe, Pine, and Pimento) that we make the fire with.

During roasting, any remaining water in the coffee, is expelled (a perfect green bean should have a water content of between 9 and 12.5%) and this weight loss has to be allowed for, by roasters!! My kitchen scales are not sufficiently accurate to record the exact weight loss!! After roasting, the beans are put in metal trays, to cool: which takes an hour or so: rested for another couple of days, in sealed containers, before grinding, and brewing. Grinding and brewing: very personal things: difficult to say which is the best method: a fine, medium or course grind, and which brewing method: I have a drip brewer, some cafeteria (French press) brewers, and a small, one cup, espresso machine: as well as the local favourite way, the most simple, and traditional method: a fine grind, and brewed in a saucepan of water, slowly heated, and stirred, the moment the first bubble appears as the water nears boiling, a little cold water is added, to keep it just below boiling; all done on a very low flame, it certainly gives the richest and strongest brew, of all the methods we have tried. AND: after all this, just one thing left; to brew a pot, relax, out on the balcony, and zap the taste buds, with it!!

My favourite drinking, is strong, black, and unsweetened. The real "wow" on the palate comes when you drink the coffee, just a few moments after eating some Jamaican hot and spicy, food: the coffee needs to be as hot as you can drink it, and the spicy/hot pepper causes the flavour of the coffee to just explode with a "Zing" on the palate (try it, and see if you can find a better word to describe the sensation!!). Now, after all this work is completed, the sun is setting, and illuminating the last of the evening mists: time to start thinking about cooking dinner, and feeding the dogs, before collapsing in front of the TV, with a few cold beers!

Oh YES, it really does look like this!! "The Golden mist". As the sun sets below the mountains to the west, and all the other conditions are perfect: some white clouds hovering over the peaks to our east, and the whole valley enveloped in a very light mist, little more than a "heavy haze", just before the sun drops out of sight, the light turns to a golden colour, as in the picture above, and a few moments later, as the disc of the sun vanishes from view, this turns to a pink colour: as the red of the setting sun, reflects off the white clouds over the eastern peaks, and illuminates the hazy-mist, which turns a lovely pink, the very air itself, appears to glow with this pink: an effect which lasts only a few moments, before the sunlight darkens into red, as do the mists, before the sun drops too low, and twilight sets in: just leaving the last of the glowing red sunset in the clouds way over to the west. It is very rare to get a picture, this good, of the effect, and the pink colour of the mist, is so very diffuse, that I have failed, with hundreds of photos, to capture it. One thing I just cannot do, is to "assess" the quality of my coffee, I have all the "cuppers criteria", but nothing to compare it with; no coffee is allowed to be imported into Jamaica ( powder-in-jars, and a few specialist mixtures containing coffee; excepted ) so we have nothing to compare it against, and make any sort of "comparative" grading of the flavour. All I can do is to assess my coffee against some powdered muck, and the scores are; 0 and 100!!! But I am biased, so let's be more accurate 2 against 98??? Today's recipe: and one with a distinct history: Banana bread.

Banana bread (this is a modern recipe) is a "sweet" variety: mix in a bowl, 4oz of butter, 4oz of sugar, beat in a large egg; and a good tot of golden rum. Sift 8oz of plain flour, a little salt, some grated nutmeg, and some baking powder, into a separate bowl, and stir together. In a third bowl, mash up 2 or 3 large, ripe, bananas, and add a little vanilla essence. Add a little from each bowl, in turn, and mix together, (optional: add raisins and chopped walnuts) repeat until all the ingredients are well mixed together (a little water may be needed, but only sufficient to create a pliable dough). Put in a bread tin, and into a pre-heated oven (350F: gas mark 4) and bake for about an hour, or until fully cooked. Tastes best, straight out of the oven, smeared with butter, or (very much a "local" taste!!) a slice of processed cheese, partially melted on top. When cold, goes well with whipped cream, or cold custard. Until next time, may I wish you all "the best of cupping". Robin Plough, friend of www.coffee4dummies.com |

Processing our coffee (part 2)

Processing our coffee (part 2)

Dried beans, (parchments) as they come off the drying trays, still with some bits of dried coffee trash, in amongst them.

Dried beans, (parchments) as they come off the drying trays, still with some bits of dried coffee trash, in amongst them.

Here we see the "workers" (Dave, on a short visit from Canada: and Chris, who works for me, looking after the coffee plantation) hulling the coffee: which has been out the sun for a while, to crisp up the parchment, to make the process a lot easier. Don't you just love "supervising", and watching other people do all the work?

Here we see the "workers" (Dave, on a short visit from Canada: and Chris, who works for me, looking after the coffee plantation) hulling the coffee: which has been out the sun for a while, to crisp up the parchment, to make the process a lot easier. Don't you just love "supervising", and watching other people do all the work? The output from the huller, a mixture of the coffee beans, and the trash from the parchment cover.

The output from the huller, a mixture of the coffee beans, and the trash from the parchment cover. Sorting the beans, we can only do a "rough" sorting, using a 1/4 inch square, wire mesh: whilst not perfect, does the job quite adequately. Its' secondary function is to sieve out as much of the small bits of trash, as possible, which makes the grading, a lot easier. The ice bucket is not used for the "human lubrication" essential during these processes: we keep the beer in the fridge, nice and cold!!!! In this climate, a bucket of ice, is all gone in an hour or so!!It is coffee, cold water, fruit juice, or a chilled soda; during the day, and the beer (our own Jamaican, Red Stripe) is reserved for the "apres toil" session, when all the work is done.

Sorting the beans, we can only do a "rough" sorting, using a 1/4 inch square, wire mesh: whilst not perfect, does the job quite adequately. Its' secondary function is to sieve out as much of the small bits of trash, as possible, which makes the grading, a lot easier. The ice bucket is not used for the "human lubrication" essential during these processes: we keep the beer in the fridge, nice and cold!!!! In this climate, a bucket of ice, is all gone in an hour or so!!It is coffee, cold water, fruit juice, or a chilled soda; during the day, and the beer (our own Jamaican, Red Stripe) is reserved for the "apres toil" session, when all the work is done.

Back in the days of sailing ships, flour was (and still is) all imported (wheat is not grown in the Caribbean, in any meaningful quantities) and supplies could run short: so the local bakers would improvise, and substitute wheat flour, with other locally available sources of starch; banana, coconut, cassava, and sweet potatoes, have all been used, creating a whole new range of "breads": ranging from sweet (cakes) to direct substitutes for the daily wheat bread.

Back in the days of sailing ships, flour was (and still is) all imported (wheat is not grown in the Caribbean, in any meaningful quantities) and supplies could run short: so the local bakers would improvise, and substitute wheat flour, with other locally available sources of starch; banana, coconut, cassava, and sweet potatoes, have all been used, creating a whole new range of "breads": ranging from sweet (cakes) to direct substitutes for the daily wheat bread.